FEATURE

Challenges in Developing Sustainable Packaging Solutions for Adhesives

Challenges in Developing Sustainable Packaging Solutions for Adhesives

By Tobias Bodenmüller, Senior Technology Expert – Development Engineering, Medmix Switzerland AG, Sennwald, St Gallen, Switzerland

This article explores the challenge of developing sustainable solutions using the example of two-component plastic packaging for adhesives.

The topic of sustainability is becoming increasingly important in the development of packaging and other consumables. Ecological and social challenges are important factors to consider when developing new products. Consequently, environmentally friendly materials and energy efficiency are taking center stage in a new approach for two-component packaging development.

By using recycled or biobased materials and harnessing energy-efficient production processes, companies can contribute to protecting the environment by reducing their carbon footprint. However, this alone is often not enough. To make products even more sustainable, the consistent use of eco-design principles is vital. For example, the reduction of materials or the use of a standard plastic with a lower carbon footprint can help to further minimize the overall ecological impact of products. In addition, the entire life cycle of a product, or the system into which the product flows, should be considered to identify further carbon reduction potential.

Figure 1: Balance between ecological, economical, and technical requirements.

The example of a sustainable solution for two-component application systems can be used to show the challenges faced during development with regards to harmonizing economical, ecological, and technical requirements. The aim is to achieve the best possible compromise and establish a viable solution that is appreciated by customers (Figure 1).

Figure 2: Tools for a simulation of the development process.

To attain this, various analysis and simulation methods are combined to form a digital development chain (Figure 2). This approach makes it possible to accurately consider the required performance, overall manufacturing costs, and sustainability of a product at an early stage of development.

Digital Simulations for More Economical Solutions

The finite element method (FEM) can be used to analyze the mechanical integrity of components. This numerical simulation is used to measure both the rigidity and the strength of the products to be manufactured. If cyclical loads also occur in the subsequent application, fatigue calculations are performed downstream to estimate the expected service life. Due to the close coupling of injection molding filling and structural simulations, manufacturing influences are directly considered in the structural calculation.

Computation fluid dynamics (CFD) simulations aid in the development of geometries for mixing two-component adhesives. Taking into account the often-complex rheological properties of adhesives and application conditions, the most efficient mixing technology can be selected or newly developed. In this context, efficiency relates to achieving a specified quality of the adhesive components to be mixed with the lowest possible pressure loss and the smallest possible mixer geometry.

Figure 3: Manifold challenges for the product development.

In parallel to numerical simulation, the injection molding process is analyzed via filling simulations before the first tool is produced. This allows problems that could occur to be identified. Suitable measures can then be taken, for example, to avoid air inclusions, move weld lines to non-critical areas, or optimize fiber orientation. Furthermore, it provides important information about the shrinkage and warping of components during cooling. As the filling process has a major impact on production costs, simulation in advance offers enormous potential for improving the cost-effectiveness of the product.

Diverse Challenges with Seemingly Minor Changes

Various scenarios are conceivable for the development of more sustainable packaging solutions. One possibility is to reduce environmental impact through incremental change, like selecting a different material. With this approach, usually only one part of the product life cycle is optimized. The aim is to continue with a largely unchanged product design to achieve the shortest possible implementation times.

A more radical approach, such as a new packaging concept, can open greater sustainability optimization potential. This usually involves a new product design that unlocks carbon savings throughout the entire product life cycle. However, to achieve the improvements, it may be necessary to adapt processing steps within the supply chain.

Figure 4: Requirements on the material selection.

The challenges in the product development of packaging solutions for two-component dispensing systems are manifold (Figure 3). Safe use of the cartridges and the storage stability of the components are important aspects that must be considered during development. It is necessary to design the products in such a way that the components in the cartridges do not react prematurely and thus impair their functionality. Regulatory requirements also play a vital role in the development of packaging solutions for two-component dispensing systems.

Material Selection

These aspects must be considered when selecting materials. If a reference product is made from a fossil-based plastic, a more sustainable material must be selected that fulfills the mechanical properties and chemical resistance of the original. To be successful in switching from carbon-intensive raw materials to more sustainable options, it is important to be able to use existing production processes and facilities. For injection molding, this means using the same machines and molds. Today, sustainable alternatives to virgin plastic are generally more expensive, as the production process is more complex and manufacturing volume lower. In the future, this difference could decrease due to economies of scale with bioplastics or legislation that makes the use of fossil fuel-based plastics more expensive, like additional taxes. Recycled "drop-ins" have the largest overlap and therefore offer great potential for more sustainable products (Figure 4). The aim here should be to use the recycled material for a sophisticated technical application in which petroleum-based plastics would normally be utilized.

Figure 5: Evaluation of recycled material.

Material Evaluation

Internationally active companies generally have a global footprint in terms of production sites. The best approach when utilizing recycled materials is "local-for-local," i.e. to use locally available materials at localized production plants (Figure 5). This supports regional approaches to the circular economy and avoids unnecessary transportation. In addition, there are generally no globally available recycled material types, as is the case with petroleum-based plastics. The consequence is that different suppliers in each region must be used. Materials from these suppliers will have varied properties. The challenge is to meet the necessary material requirements for the safe use of the product.

When using recycled material, there may be color deviations between different production batches, as well as defects such as black dots. These have no effect on product performance. Due to their widespread use as packaging material, there is a large selection of post-consumer recycles (PCR) for standard plastics such as polypropylene (PP) or polyethylene (PE). For technical plastics such as polyamide (PA) or polybutylene terephthalate (PBT), PCR material streams are generally not yet available in sufficient quantities. A post-industrial recycle (PIR) could be used for these materials.

Figure 6: Performance of sustainable solution.

Consistent Performance

A real drop-in solution uses more sustainable material but meets the same application requirements for standard items — although these are varied for a modern application system (Figure 6). The dimensions and material properties of the components must adhere to specifications so that they function perfectly in combination with other individual parts, e.g. when closing the cartridge with a plug, or that the friction between the piston and cartridge meets specifications. It is also important to ensure that the system remains tight under changing climatic conditions. During use, loads occur, so the relevant components must have a corresponding mechanical stability to comply with the specified burst or drop strengths.

- The first phase, "upstream," comprises the extraction of raw materials and production of the precursors needed to manufacture the product.

- The second phase, "core," refers to the transportation of the preliminary products and the actual manufacture of the product, including packaging.

- The third phase, "downstream," covers the distribution, use, disposal, and recycling of the product. Potential for optimization can be uncovered by identifying weak points in the system.

Cradle-to-Gate Assessment

Manufacturers are often not aware of the environment in which their products are used. To get a result quicker, the LCA can be simplified. Therefore, many companies consider the environmental impact of the manufactured product within their system boundaries, which can be directly influenced by them. This scenario can be a cradle-to-gate analysis. Looking from the cradle to the factory gate allows companies to assess the environmental footprint of a product or service and identify potential hotspots for environmental impact during the manufacturing process. This understanding can promote more ecological decisions in terms of design, material selection, and production, thus improving sustainability.

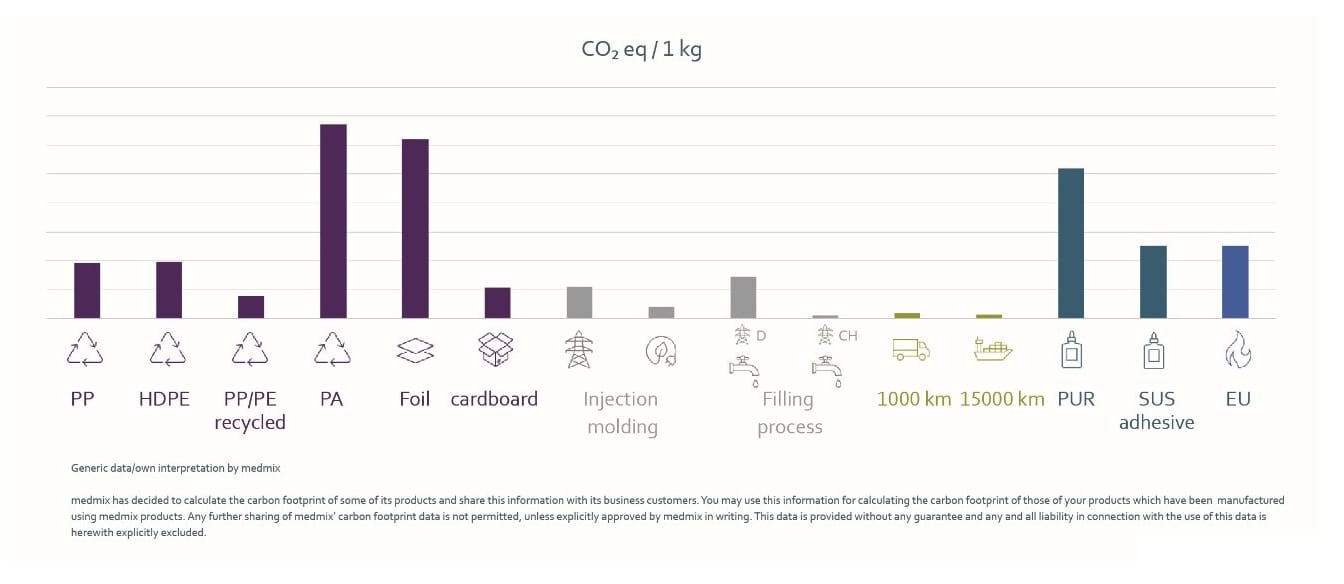

As a guideline, the greatest potential exists in the use of materials and the power supply for the manufacturing process. Figure 8 "Global Warming Potential (GWP) for materials and processes" shows the CO2 equivalent (CO2 eq) of different materials and processes. This overview provides an initial indication of where the influencing factors for optimization may lie. Together with the respective weight of the component or the quantity processed, this offers the greatest savings potential.

Figure 7: Optimization across all phases of a product life cycle.

Calculating the Ecological Footprint

To calculate and simulate the ecological footprint of a product, medmix uses life cycle assessment (LCA) software. The LCA evaluates the environmental impact of a product over its entire life cycle — from raw material extraction to disposal. The product life cycle can be divided into three phases (Figure 7):

Figure 9: Drop-in solution - using the same processes as for fossil-based plastics.

Drop-in Solution

One example of a sustainable solution is the use of recycled plastic. By optimizing the product life cycle phases "upstream" and "core," the environmental impact can be reduced. This step-by-step approach can be implemented as a drop-in solution, as existing processes and production resources are suitable for manufacturing the product. The savings potential for this use case relates to the different CO2 eq of the plastic materials, as it is assumed that electricity from sustainable sources is used to manufacture the products in every case (Figure 9).

Figure 8: The Global Warming Potential (GWP) for materials and processes.

Figure 10: Simplified visualization of a product system.

According to an internal LCA, 38 % of CO2 emissions can be saved in this example. The advantage of this step-by-step approach is that no adjustments need to be made to further processing steps, such as the filling process or application routines, on the user side. This solution therefore represents the lowest barrier to entry for the implementation of more sustainable products.

Cradle-to-Grave Assessment

Greater savings potential can be identified by extending the scope of the analysis. In a cradle-to-grave analysis, the environmental impact of a product is considered from raw material extraction to disposal at the end of the product life cycle. This enables a comprehensive assessment of the environmental impact. The aim is to be able to make more sustainable decisions in terms of product design, material selection, use, and recycling or disposal. Cradle-to-grave analysis makes it possible to gain a holistic understanding of the environmental impact of products and thus develop successful strategies to reduce this.

Defining the Scope of the Study and Product System

First, the product system to be analyzed must be defined (Figure 10). In this example, the environmental impact of the packaging and the contents of a two-component adhesive are added. In order to clearly delimit the analysis of the system, the products in which the adhesive is used are not part of this analysis. The LCA is designed to compare two different packaging systems in terms of their environmental impact, so the bonding process — including preparation, cleaning, and use of primers — the use and effect of dispensing equipment and the labeling and packaging of the filled products are not considered.

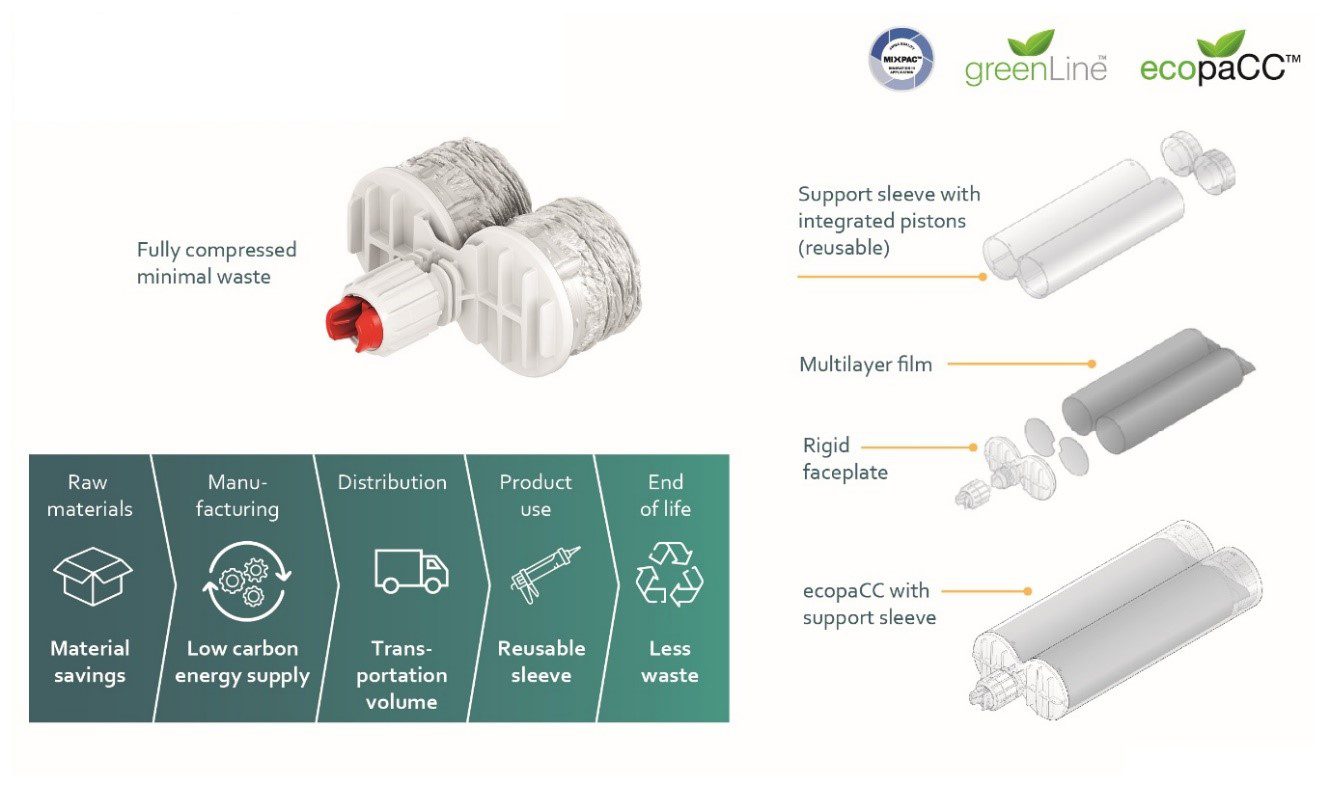

Figure 11: Holistically sustainable: packaging concept according to ecodesign principles.

Hotspot Analysis

With an LCA, the hotspots with the greatest optimization potential can be identified. A distinction must be made as to which areas can be influenced directly and those which can only be changed indirectly or not at all.

Developers of high-quality packaging solutions can influence the environmental impact, mainly in the upstream and core phases. Examples include the use of green energy or more sustainable materials (see drop-in solution). Furthermore, material usage can be reduced through new packaging concepts (see ecological packaging concept). In the majority of the "downstream" phase, there are no or only limited optimization options.

In this internal LCA, the adhesive accounts for the largest proportion of CO2 emissions, but the packaging manufacturer has no direct influence over this. However, should the manufacturer achieve lower CO2 emissions through optimization, the positive environmental impact of the packaging would be proportionately greater. A sustainable improvement can therefore only be attained together with all those involved in the value chain. However, packaging developers can also help adhesive manufacturers to reduce the volume of adhesive remaining in the mixer after use through new developments. This can be achieved through more efficient mixing geometries. At the end of the life cycle, it is possible to directly influence the environmental impact again through adapted concepts, e.g. through product solutions that enable less waste and/or residual adhesive.

Ecological Packaging Concept

A new solution based on ecodesign principles can open up additional potential for improving sustainability (Figure 11). With this radical and innovative approach, advancements can be achieved in all phases of the product life cycle. Compared to the drop-in solution, optimization is also possible in the "downstream" phase. By using flexible packaging for the majority of the cartridge, material can be saved, which reduces the transportation volume. A reusable support cartridge was developed for this application, which helps to lower the ecological footprint. At the end of the life cycle, only the disposable part of the packaging is thrown away, significantly reducing the amount of waste. The advantage of this solution is that a large material and waste saving is achieved through the packaging design and reusable support cartridge respectively, improving the sustainability of the product. Overall, this packaging concept is an example of how ecological and economic requirements can be reconciled in product development to create a sustainable solution.

Figure 12: GWP for a "cradle-to-gate" solution.

Taking the Entire Value Chain into Account

The LCA shows the savings compared to the standard solution. In the "upstream" and "core" phases, the CO2 eq (calculated on the basis of 1000 reuse cycles) can be reduced by using less material and taking eco-design principles into account with the reusable support cartridge. The aim of the analysis is to objectively assess the environmental impact; the existing solution has advantages in terms of adhesive use due to the low residual volume after use. At the end of the life cycle, the new packaging concept with the reusable support cartridge can significantly reduce the volume of waste and thus reduce the CO2 eq.

Joint Efforts for More Successful Products in Line with Current Trends

In summary, it can be said that sustainability is playing an increasingly important role in the product development of two-component dispensing systems for adhesives and sealants (Figure 12). To overcome ecological and social challenges, economic, ecological and technical requirements must be harmonized.

A digital development process with simulation tools can help to form a closed simulation chain and make a statement on sustainability. Rapid success with minimal changes can be achieved by implementing drop-in material solutions. When using recycled material, however, it is important to know the requirements when selecting the material to deliver a product that meets the specifications.

By using LCA software, the environmental impact can be made visible, highlighting optimization potential for new developments. More sustainable packaging concepts can achieve savings throughout the entire life cycle. It is vital to consider the entire value chain to avoid a shift in environmental impact. Consequently, the path to a circular solution can only be achieved by all participants in the value chain working together.

Learn more about medmix Switzerland AG at www.medmix.swiss/en-us.

Opening image courtesy of borchee / E+ / Getty Images.