STRATEGIC SOLUTIONS

Mastering Key Performance Indicators for Long-Term Success

Opportunities to increase market share will increase when companies are pre-positioned for growth in a resilient and scalable way.

The PFAS Discussion: Update 2025

By Lisa Anderson, Founder and President, LMA Consulting Group

By Robert Kramer, Director, The ChemQuest Group, Inc.

Fewer, smarter, and well-communicated KPIs—backed by accountability and leadership engagement—are the key to turning metrics into meaningful operational improvements.

Your company has undoubtedly developed key performance indicators (KPIs) for your operation. Depending on your specific products, facilities, personnel, etc., these KPIs likely focus on areas such as production volume, on-time delivery, production costs, and environmental health and safety (EH&S), among others.

KPIs are important gauges of your company’s productivity and efficiency, but simply having KPIs does not guarantee success. Oftentimes, problems can arise when:

- Trying to establish too many KPIs

- Not establishing the "best" or most productive KPIs

- Not prioritizing KPIs effectively (i.e., treating them all the same)

- Using ineffective or even inaccurate dashboards (leading to lower productivity)

Keep It Simple

The most important thing to keep in mind when developing, tracking, and analyzing KPIs is to keep things as simple as possible. I once worked with a company that had developed over 80 KPIs in manufacturing alone. Even worse, they were focused on simply tracking performance and not identifying problem areas or making improvements.

Our team worked with the company to shrink the KPI list down to about eight in total, and – perhaps more importantly – we helped them shift their philosophy away from only tracking data to analyzing and taking corrective actions. We focused on accountability, illustrating the beneficial impacts that KPIs can have and emphasizing their individual roles in achieving top performance.

While the training was enough to inspire this particular team to work together and get the company going in the right direction, other organizations might have more serious issues. In these instances, full culture change, driven by accountability management, may be needed.

Additional best practices for KPIs include:

- Engage as many colleagues as possible during the development process — Team members from different departments will bring diverse perspectives and insights

- Ensure relevance and consistency — Be sure you’re targeting aspects of your operation that are meaningful and impactful to the bottom line

- Be strategic — Avoid applying blindly or trying to track everything; aimless measurement leads to wasted time and resources

- Communicate with relevant teams and company leadership — Sharing information keeps everyone engaged and on the same page

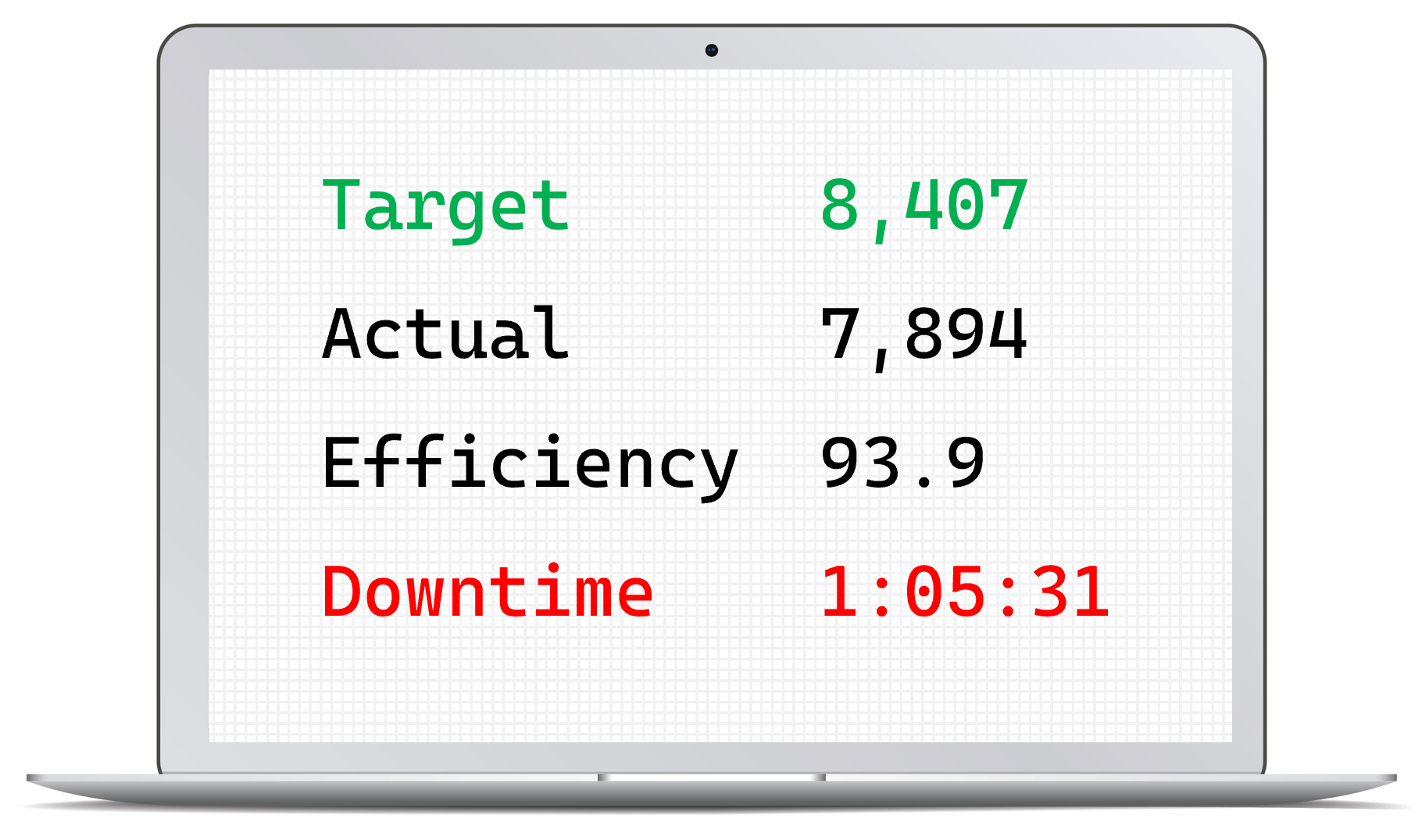

Image 1: Example TAED dashboard. Image courtesy of ChemQuest.

Tracking Metrics on the Shop Floor

It can be difficult to achieve optimal performance if you are operating blind. One of the visuals recommended across plant shop floors is the TAED dashboard, which highlights the process target, actual, efficiency, and downtime:

- Target — Real-time production target driven by planned production rate

- Actual — Actual production rate

- Efficiency — Ratio of target to actual (i.e., how far ahead/behind production is running by percentage)

- Downtime — Accumulated unplanned stoppage time (updated in real time, this encourages a focus on a key actionable improvement area)

This simple dashboard for supervisors and shop floor personnel shows clear and achievable metrics that everyone on the team understands, and it helps the frontline production teams be focused on their activities in real time. The TAED can provide the teams with a sense of urgency regarding what has to happen to get back on track.

KPI Scorecards

KPI scorecards are also critical to the performance improvement process within your organization. It’s important to develop KPI scorecards that have buy-in and involvement from all the team members, as well as senior leadership.

The most important element of this process is to establish realistic, attainable goals. The team needs to realize that the KPIs aren’t simply a “pie in the sky” dream, but they represent real numbers that the company can actually achieve.

At the same time, your team members need to be accountable for what they control. You can’t have areas within your organization where teams or individuals are able to pull down others because the organization has no accountability management. On the other end of the spectrum, make sure that you’re giving constant communication and praise when things are going well. Accountability and positive feedback will both do wonders for morale within your organization.

Leadership needs to be involved in the KPI scorecard development process, and they can do this simply by asking questions. When senior management asks questions of those responsible, they’re going to get more attention and therefore results.

Company leadership should also be engaged in the scorecard review process. Depending on your organization, it may make sense to have structured KPI performance reviews where teams responsible for the KPIs deliver presentations on their progress (e.g., weekly for front-line operations such as supervisors or team leaders, monthly for operations management, and possibly quarterly reviews with senior management). This provides the opportunity for an effective two-way exchange between management and those responsible on the shop floor.

Team members should be informed and educated regarding how their improvements (or the lack thereof) are having an impact on the business. During the review meetings, for example, the leadership team can provide feedback and further the discussion. The key is to keep the exchange as positive as possible to drive motivation within the team.

Success Builds Success

As you go through the KPI improvement process, you’ll want to be able to show your results and validate them through a third party (e.g., the company’s accounting department). This carries a lot of weight by assuring the accuracy of your findings, providing more credibility with senior management.

In a best-case scenario, this step will enable you to align your improvements to the P&L and illustrate a demonstrable impact on the company’s bottom line. The result will be a favorable interest level from senior management, which can translate to increased access to resources for future initiatives that further support your quest for operational excellence.

To learn more, reach out to the author at rkramer@chemquest.com or visit chemquest.com.

Image courtesy of Galeanu Mihai / iStock / Getty Images Plus