FEATURE

Accelerating Collaborative Sustainability in the Tapes Industry

Rethinking Transparency and Sustainability in Circular Packaging with Digital Product Passports

Opportunities to increase market share will increase when companies are pre-positioned for growth in a resilient and scalable way.

Rethinking Transparency and Sustainability in Circular Packaging with Digital Product Passports

By Lisa Anderson, Founder and President, LMA Consulting Group

By Adhesive Specialists at Henkel AG & Co., Düsseldorf, Germany

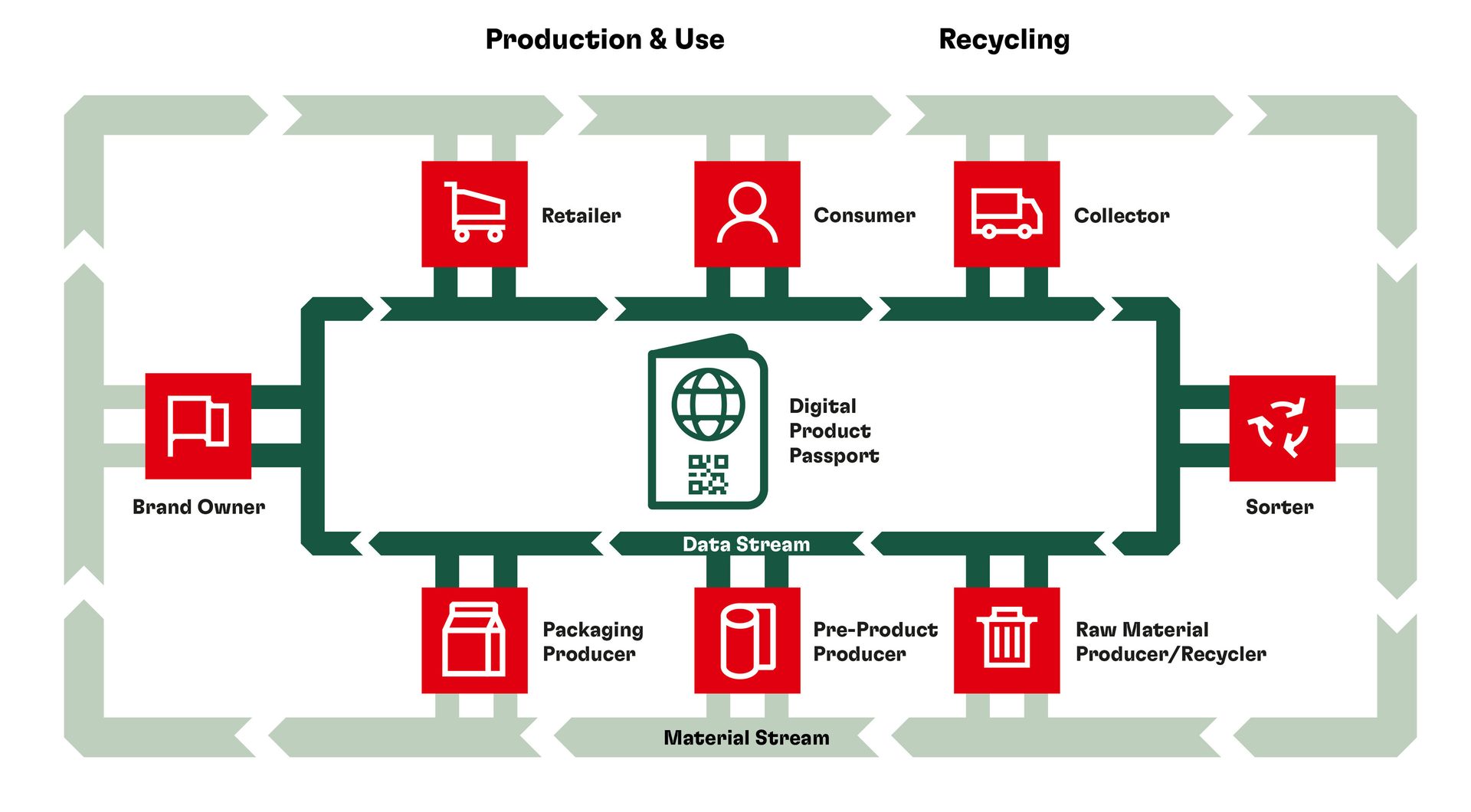

By integrating recyclability and lifecycle data, digital product passports help improve sorting accuracy and support the circular economy.

The packaging industry is facing a dual challenge, with consumers demanding sustainable solutions, while increasingly stringent regulations require greater resource efficiency in production. How can companies fulfill these expectations and, at the same time, ensure transparency along the entire supply chain? The digital product passport (DPP) could be the answer. How does it work in practice, and what opportunities does it bring to the industry? In a joint project with the open traceability and DPP platform R-Cycle and the flexible packaging converter Korozo Group, Henkel has demonstrated the benefits that can be achieved.

The pressure to develop environmentally compatible and resource-efficient packaging has increased tangibly. At the same time, global supply chains require greater transparency along the value chain in order to ensure that the origin of the materials, their processing, and the end of the life cycle are traceable.

One key trend in the packaging industry is the shift toward a circular economy. The goal is not only to make packaging more efficient but also to return it to the production cycle at the end of its life. For this to happen, the materials need to be recyclable and the raw materials used need to be derived from sustainable sources wherever possible. In addition, there needs to be clear rules for disposal. Digital solutions are becoming increasingly important in the efforts to satisfy these requirements.

Driving Transparency

Against this backdrop, focus is turning to the DPP. This is a key instrument in creating a digital record of the necessary information about the composition, life cycle, and sustainability aspects of a product and making this information accessible. Driven by regulatory requirements such as the European Union’s Ecodesign for Sustainable Products Regulation (ESPR), the DPP will become mandatory in many industries from 2027.

The digital data set contains information such as the material composition, technical specifications, and recyclability of a product. Each product is allocated a unique identifier, accessible via a suitable marking, such as a QR code or RFID tag, to facilitate its traceability along the value chain. The quality of the assigned data recorded is crucial here. Companies along the value chain need to provide the relevant information, which is prepared in a standardized format and made accessible to all stakeholders.

The DPP enables the seamless traceability of packaging along the supply chain, creates transparency, and facilitates legal compliance.

More Recycling

In the packaging industry especially, the DPP not only satisfies regulatory requirements but also significantly improves the sustainability of packaging. Philippe Blank, head of circular economy at Henkel explained this concept, "The DPP enables the seamless traceability of packaging along the supply chain, creates transparency and facilitates legal compliance."

A functioning circular economy requires recyclable and ideally a high proportion of recycled raw materials to be already integrated into the procurement phase; these are then transferred to a design that considers various end-of-life scenarios. The goal is to recover materials for use in place of virgin material.

"Reducing the use of raw materials and minimizing the resources needed are crucial for ensuring a sustainable future," explained Blank. Detailed material data simplify sorting and recycling, helping to preserve resources and increase the recycling rate.

Spotlight on Adhesives

In a joint project with Korozo Group, a flexible packaging converter, and R-Cycle, a platform based on open standards for the operation of DPPs to ensure the traceability of packaging, Henkel decided to actively test and implement the DPP as part of its continuing commitment to make every package sustainable. The Loctite Liofol solvent-free adhesive developed by Henkel is used to reliably laminate stand-up pouches. It is characterized by its chemical and thermal resistance, making it suitable for aggressive filling goods, pasteurization, and high-speed packaging lines with a high seal temperature.

This example, trialed in a Henkel Consumer Brands' finished good, shows what the DPP looks like in practice. Each package produced with Loctite Liofol is given a QR code that is linked with the R-Cycle DPP. This ensures that technical data, safety information, and environmental aspects can be accessed directly. Henkel is working with R-Cycle to extend this traceability, thus optimizing the disposal and recyclability of the product as well.

Dr. Benedikt Brenken, director R-Cycle, explained, "The application with Henkel shows very well how relevant information on the packaging components used — in this case the adhesive — can be recorded in the DPP and made available throughout the entire product life cycle. In this way, we create a defined level of transparency and easy traceability along the value chain. We see this as a decisive advantage regarding the constantly growing information demand."

In addition, Henkel records the carbon emissions generated in the manufacture and use of the lamination adhesive in the DPP. This information is critical to complying with the ESPR requirements and to assessing the product’s carbon footprint throughout its entire life cycle.

The information recorded in the DPP enable end-of-life companies to properly manage the disposed packaging when it arrives to the sorting and recycling center, positively contributing to circular economy and recycling ratio.

As part of a joint project with R-Cycle, Henkel decided to actively test and implement the DPP with a pilot project using Loctite Liofol solvent free adhesive to reliably laminate stand-up pouches.

Shaping the Transition for Processes and Materials

"We are on track to be able to offer each customer a sustainable product that is either derived from sustainable sources or has an outstanding recyclability profile," explained Blank.

As a supplier and brand owner, Henkel is in the unique position of covering a large part of the value chain. The company reports that 80% of the environmental footprint of a product is defined in the design phase. This knowledge is used to provide advice to clients early in the process

The product carbon footprint (PCF) of individual components and of the product overall has a particularly crucial role to play here. In this connection, Henkel has established extensive capacities to identify savings potential and provide reliable data for DPPs and reporting requirements. These data are especially relevant to the recyclability of packaging and the obligation to use recycled raw materials.

"We align our work with leading assessment methods and design guidelines and are actively working on new test methods," said Blank. The packaging industry is currently undergoing a profound change that is resulting in a significant shift in the materials used. These changes are also impacting existing recycling processes. The goal is to close the gaps through the active research and development of new test methods in order to prepare the company and its customers for pending legislative changes.

Using a DPP will become more and more important in the packaging industry, increasing transparency in the supply chain, paving the way for better recycling, and fostering additional trust of customers and partners. It will be a key lever for driving innovation and increasing competitiveness. In addition to sustainable product development, the DPP is paving the way for the creation of new business models based on digitalization and the circular economy.

Learn more about Henkel at www.henkel.com.

Images within the article are provided courtesy of Henkel. Opening image credit of Bombaert / iStock / Getty Images Plus.