FEATURE

Innovative Bio-Based Polyether Polyols

Innovative Bio-Based Polyether Polyols

By Fanying Bao, Changxun Ju, Kuanliang Bao, and Chunxing Zhang, Wanhua Chemical (America) Co. Ltd., Yantai, Shangdong Province, China

Biobased polyether polyols with vegetable oil are developed through special catalysts, helping to create products with specific characteristics depending on biobased content.

Achieving green manufacturing is a key step to achieve the global goal of carbon neutrality. According to the plan of the U.S. biomass technology roadmap, 25% of petroleum-based organic compounds will be replaced by biobased compounds by 2030. According to the EU's industrial biotechnology vision plan, biological-based raw materials will replace 6% to 12% of chemical raw materials by 2030. In China's 13th five-year plan for the development of the biological industry, biobased products are to replace 25% of petroleum-based chemicals. Biobased polymers have broad prospects for development.

Biobased products with vegetable oil as a raw material have the advantages of being renewable, degradable, and non-toxic. Through chemical modification, vegetable-oil-based polyols are prepared. This vegetable oil-based polyol replaces petroleum-based polyol to synthesize polyurethane foam, which can not only save energy and reduce emissions, but also helps protect the environment, and is an important path to achieve sustainable development1-4.

Wanhua has developed biobased polyether polyols with vegetable oil through special catalysts and developed products with different characteristics according to the different biobased content. This series of products is mainly used to prepare block foam (slow rebound and high rebound), molded foam (high rebound and slow rebound), and semi-rigid foam. This article introduces the basic characteristics of Wanhua’s biobased polyol series products, as well as the test results and application guidelines in different fields (household sponges, automotive interiors, etc.). In the field of furniture, foam products prepared from biobased polyols have similar physical properties to petroleum-based polyether, and have better compression resistance and air permeability; In terms of automotive high-rebound cushion and dashboard, the addition of less than 30% has little impact on the physical properties of the foam.

Table 1: Technical parameters.

Experimental

Raw Materials and Instruments

See Table 1 for properties of biobased polyol FB340 and FB350 and petroleum-based polyether F3156, toluene diisocyanate (TDI, 80/20), W8223B (Wanhua Chemical Group Co.,Ltd). Surfactants (B8244, B8734) and catalysts (33LV, T9) are from Evonik.

The Jsf-550 high speed dispersing machine is from Shanghai Pushen Chemical Machinery Co. Ltd. The Z005 universal testing machine is from zwick/roell group, Germany. The Bld-hf52 falling ball rebound tester is from BlackRock Instruments Co., Ltd.

Foam Preparation

According to the slabstock foam formulation in Table 2, the raw materials of each component except TDI were accurately weighed. The mixture was stirred. The TDI was weighed and blended with the polyol mixture. It was stirred vigorously for 8s, and then quickly poured into the wooden foaming box. The reactivity was recorded. The foam samples were cured for 48 hours before physical properties were measured.

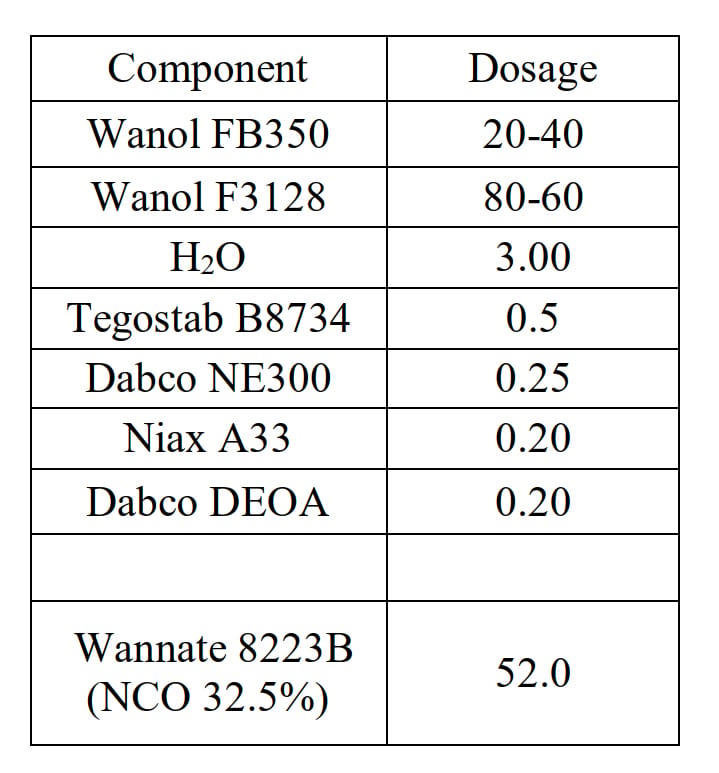

Table 3: High resilience molded foam formulation.

Table 2: Formulation of slabstock foam.

Table 4: Physical performance test reference standard.

The HR molded foam was prepared according to the formulation above. The mold temperature was set at 55-60 ℃, The foam properties were measured after 48 hours of room-temperature curing.

Physical property measurement

Foam odor is measured according to PV 3900-2019, and the classification is as follows: Grade 1 — not easy to feel; Level 2 — can be felt, but not annoying; Level 3 — can be obviously felt, but not annoying; Level 4 — annoying; Level 5 — very annoying; Level 6 — intolerable.

Figure 1: Carbon footprint of biobased polyether and common petroleum-based polyether.

Results and Discussion

Carbon reduction effect of FB340 and FB350

WANOL® FB340 and FB 350 adopt the green degradable vegetable oil synthesis process, and the biobased carbon content is 37% and 51% respectively. Compared with conventional petroleum-based products, it can reduce the carbon footprint by 30-50%. The carbon dioxide emission produced by the production of 1kg FB350 is only 50% of that of ordinary petroleum-based polyether (from cradle to gate), which can make a strong contribution to the end-users to reduce carbon emissions, as shown in Figure 1.

Table 5: Carbon emission of foam.

For end users, taking foam with a density of 25kg/m3 as an example, using FB350 to produce 1kg foam products can reduce carbon dioxide emissions by 0.58kgCO2 eq. compared with petroleum-based F3156, as shown in Table 5.

Figure 2: Odor comparison of foam prepared by different polyether polyol.

Odor and VOC of FB340 and FB350

The odor of the slabstock foam with a density of 25kg/m3 based on formulation 2 was evaluated using PV3900-2019 method (80 ℃, 2h), and the result is shown in Figure 2.

Table 6: Foam VOC test (10L bag method).

The foam prepared by biobased polyether FB340&350 has the same excellent low odor and VOC as those in foam from Wanhua's low-VOC petroleum-based polyether polyol. The VOC results meet the requirements of high-end furniture and automobile users and helps provide users with a healthier and environmentally friendly customer experience.

Table 7: physical properties.

Application of FB340 and FB350 in furniture foam

The physical properties of the foam (25 kg/m3) prepared with the formula (Table 2) are as follows:

Table 8: Effects of different FB350 dosage on the properties of foam.

It can be seen from the results in Table 7 that the physical properties using biobased polyol FB340 or FB350 are very close to those using petroleum-based polyether F3156 and have better compression resistance than soybean-oil-based and palm-oil-based polyols.

Application of FB340&350 polyols in car seat foam

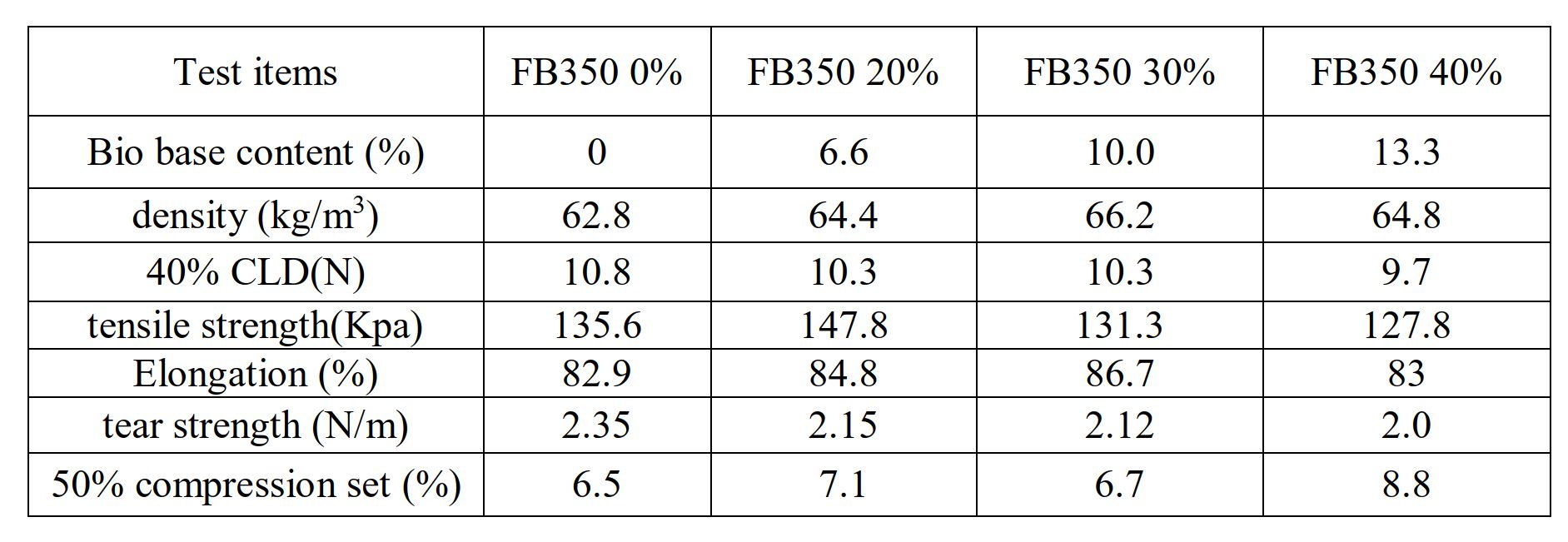

Biobased high-resilience cushion foam was prepared with the formula in Table 3. The effects of different additions on the physical properties of foam were investigated, as shown below.

It can be seen from Table 8 that with the increase of biobased polyol content, the biobased content of foam gradually increases, more than 10%. Under the conditions of similar density, the hardness and tensile strength decrease slightly, and the elongation at break remains unchanged. This may be due to insufficient crosslinking and strength reduction caused by the increase of FB3505. Therefore, the additional amount in the formula of a high-resilience seat should be controlled to be less than 30%.

Conclusion

Biobased polyols FB340 and FB350 have the characteristics of high biobased content, low carbon, environmental protection, low odor, and low VOC. They can be used in furniture and automotive applications. The physical properties of the foam with FB 340 or FB350 are comparable to those of petroleum-based polyols, but with better compression resistance. When used in less than 30% in the field of high-rebound foam, little negative impact on its physical properties were observed. Further research is still ongoing.

Learn more about Wanhua at https://en.whchem.com.

"Innovative Bio-Based Polyether Polyols" 2022 Polyurethanes Technical Conference 05-07 October 2022, National Harbor, MD, USA, Published with permission of CPI, Center for the Polyurethanes Industry, Washington, DC.

References

1. Dale B E. “Greening”the chemical industry: Research and development priorities for biobased industrial products[J]. JChemical Technology & Biotechnology, 2003, 78(10): 1093-1 103.

2. Zhang C., Garrison T.F., Madbouly S.A., et al. Recent advances in vegetable oil-based polymers and their composites [J]. Progress in Polymer Science, 2017,131(2) :119 -131.

3. Zhang Zipeng, Gu Lixia. Biodegradable polyurethane [J]. New chemical materials,1999, 27(10): 23-25.

4. Pan Meijuan, Wang Xiaohui, Yao Cheng. Synthesis and applications of vegetable oil-based polyols[J], Modern Chemical Industry, 2007, 27(S2):521-524

5. Heming, Shanmeiling, Shiyijun, et al. Application of castor oil polyether polyol in flexible polyurethane foam [J]. Polyurethane Industry, 2009, 24(6):33-36.

Opening image courtesy of ipopba / iStock / Getty Images Plus.