FEATURE

Utilizing Biobased Materials to Enable Sustainability in Hot-Melt Pressure-Sensitive Adhesives

Utilizing Biobased Materials to Enable Sustainability in Hot-Melt Pressure-Sensitive Adhesives

By Allison Luciano, Business Director Specialty Tapes & Labels NA, Henkel Corp., Bridgewater, New Jersey

A biobased adhesive helps label manufacturers achieve their sustainability goals while also meeting their end-user requirements.

Sustainability has become much more than a buzzword in the packaging industry. It’s now a necessity for brand owners and suppliers in the packaging industry. According to Shorr’s 2025 Sustainable Packaging Consumer Report,1 the change in the consumer attitude toward sustainability is significant. Over half (54%) of respondents reported deliberately choosing products with sustainable packaging in the past six months. Even more compelling, 90% said they are more likely to purchase from a brand or retailer if its packaging is eco-friendly. Consumer preferences are driving the importance and priority of corporate sustainability initiatives. Pressure from brand owners to move to more sustainable packaging is encouraging suppliers in the packaging industry to collaborate closely with customers and vendors to find innovative solutions. The move to sustainable materials and constructions, however, is complex; as well as exploring many possible solutions, the variety of assessment criteria for sustainability adds to the challenge. There is typically no singular approach and often a multitude of changes are necessary to enhance the sustainability of a package. Pressure-sensitive adhesive (PSA) labels used in packaging applications are no exception.

Pressure-sensitive adhesive labels consist of three key components: facestock, release liner, and adhesive. In recent years, sustainable facestocks have gained significant attention, with various options now available, including recycled paper and film. Facestocks made with post-consumer waste offer an environmentally responsible choice, as they are derived from materials that have been used, discarded, and recycled into new facestocks. Additionally, opting for thinner facestocks helps minimize material usage and lowers the carbon footprint.

Unlike facestocks, release liners present fewer sustainable alternatives, as they are typically non-recyclable and often end up in landfills. However, transitioning to a linerless label construction can eliminate the release liner entirely, significantly reducing landfill packaging waste. With sustainable solutions available for facestock and the potential to remove the release liner, the focus has shifted to making the adhesive more environmentally friendly.

Pressure-sensitive adhesive advancements for sustainable labels to date have been focused primarily on water-based technologies. However, rubber-based hot-melt PSAs make up a significant portion of the packaging labels market. This is because there are many advantages to hot-melt PSAs, making them a desirable choice for label manufacturers. For example, hot-melt PSAs are easier to process compared to water-based adhesives. Processing advantages include easy application, fast line speeds, and no energy consumption for drying. Also, as 100% solids materials, hot-melt PSAs inherently have low levels of VOCs. Hot-melt PSAs also exhibit excellent performance characteristics featuring aggressive adhesion and superior tack that allow the formation of strong bonds to a wide variety of substrates, including low-surface-energy materials like polypropylene and polyethylene plastics. Until recently, attempts to utilize more sustainable raw materials in hot-melt rubber-based PSAs has not yielded commercially viable options due to a trade-off with adhesive performance. Sustainable hot-melt PSAs have not been able to meet the demanding end-user requirements in the label space.

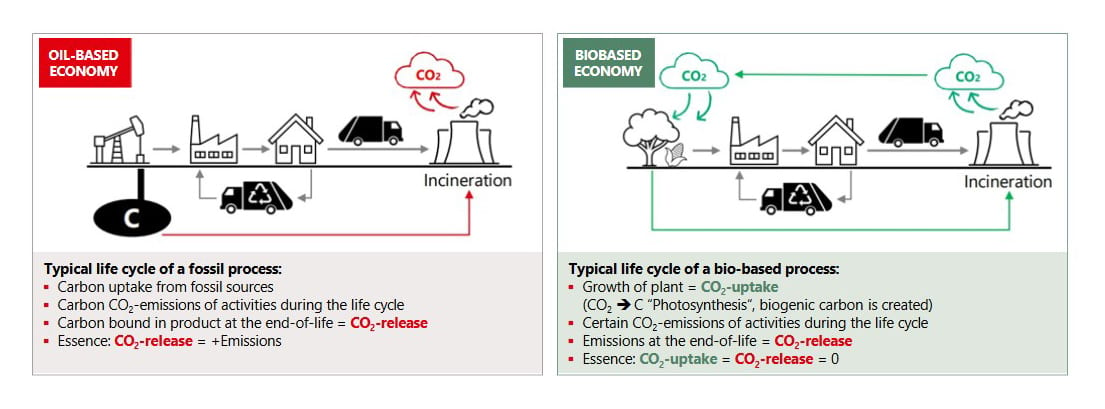

Henkel has met this challenge with TECHNOMELT® PS 5052 ECO™ adhesive. The adhesive incorporates biobased raw materials that offer a sustainable alternative to traditional raw materials derived from fossil fuels. Fossil fuels, such as crude oil, are non-renewable resources that take millions of years to replenish. Unlike fossil fuels, biobased materials are derived from plants, which can be regrown, making them a renewable source. These biobased materials enable a transition towards a more circular economy. The use of biobased materials in pressure-sensitive adhesives has become increasingly important as label manufacturers seek to move toward more sustainable solutions.

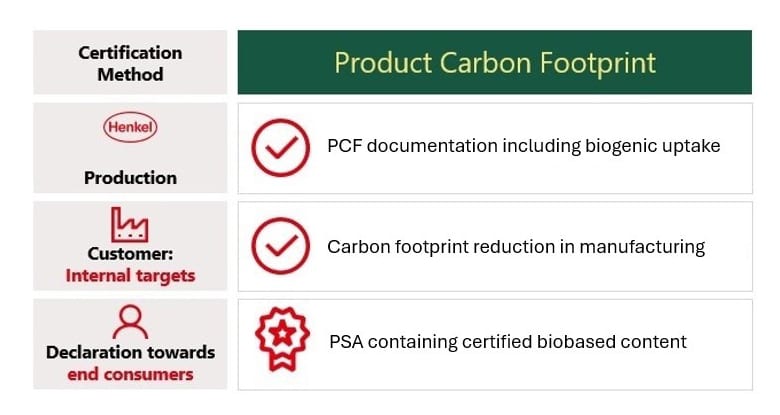

Henkel is committed to leadership in sustainability. The adhesive is an innovative biobased PSA solution for labels and contains 52% USDA certified biobased materials. USDA Certified Biobased Products assure the label manufacturer that the adhesive contains a verified amount of renewable biological ingredients (referred to as biobased content).

Henkel conducts standardized Life Cycle Assessments (LCA) that cover all environmental impacts during production, use phase, and disposal as well as the associated upstream and downstream processes (e.g. production of raw materials). Impacts include all environmentally relevant withdrawals from the environment (e.g. bio-mass, crude oil) and emissions into the environment (e.g. waste, carbon dioxide emissions). A comparative cradle-to-gate LCA between TECHNOMELT PS 5052 ECO adhesive and a traditional fossil-based hot-melt PSA shows a reduction in product carbon footprint. A roughly 16% emission reduction (including biogenic uptake and excluding use-phase and end-of-life emissions) was calculated when consuming the Henkel adhesive versus the traditional hotmelt made with fossil-based materials.

As mentioned previously, hot-melt PSAs are known for their aggressive adhesive performance. They combine strong adhesion and superior tack with balanced cohesive strength. One historical disadvantage of PSAs enabling sustainability has been inferior adhesive performance; however, Henkel’s innovative formulation using biobased materials maintains the superior performance needed in demanding labeling applications. The biobased adhesive performs as well as leading label-grade hot-melt PSAs in key performance areas. It has aggressive peel adhesion balanced with good shear cohesion. Since labels are used in many e-commerce and logistics applications, ensuring strong bonds to corrugate substrates is critical. Henkel's adhesive not only forms excellent bonds with corrugate substrates but also achieves superior fiber tear upon removal.

Handling and processing of the biobased adhesive is equivalent to traditional hot-melt PSAs. There is no need for dedicated equipment. Changeover is seamless, and existing cleaning protocols and materials can be utilized. The adhesive processing temperature is comparable as is thermal stability.

With sustainable packaging becoming increasingly more important to consumers based on their buying preferences, supplying eco-friendly packaging is a growing top priority for suppliers to the packaging industry. Sustainable packaging is crucial for minimizing environmental impact by reducing waste, conserving resources, and promoting a circular economy. PSA labels are an integral part of sustainable packaging. TECHNOMELT PS 5052 ECO adhesive helps label manufacturers achieve their sustainability goals while also meeting their end-user requirements.

For more information, contact Allison Luciano at allison.luciano@henkel.com. Learn more about Henkel at www.henkel.com.

References

1. The 2025 Sustainable Packaging Consumer Report | Shorr Packaging

Opening image courtesy of Arkadiusz Warguła / iStock / Getty Images Plus