FEATURE

Accelerating Collaborative Sustainability in the Tapes Industry

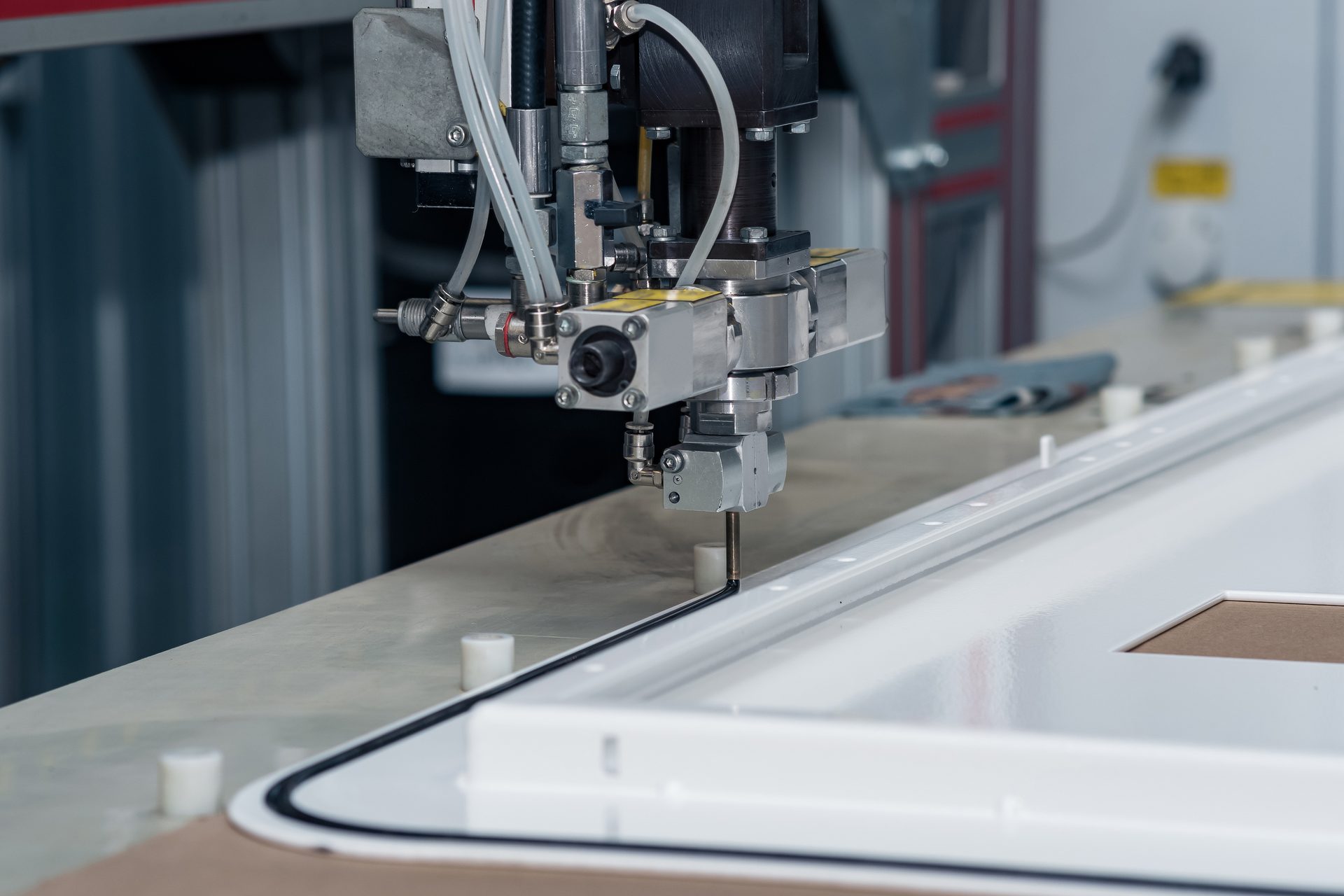

Using AI and Machine Vision in Automated Dispensing

Opportunities to increase market share will increase when companies are pre-positioned for growth in a resilient and scalable way.

How AI and Machine Vision Are Revolutionizing Automated Dispensing

By Lisa Anderson, Founder and President, LMA Consulting Group

By Ellie Gabel of revolutionized.com

AI and machine vision are emerging as the latest technological evolution to help address inherent flaws in traditional automated dispensing.

Compared to conventional dispensing robots, modern automated machinery represents a significant technological leap forward. However, artificial intelligence may soon render it outdated. These machines are static and rigid, unable to adapt as needed. This is why intelligent technology is emerging as an alternative.

AI and machine vision are revolutionizing automated dispensing. Beyond addressing long-standing pain points, they are optimizing paths and accelerating turnaround times. How will this technology impact manufacturing? More importantly, how soon can manufacturers use it?

The Shift from Automated to Intelligent Dispensing

While automated dispensing technology is relatively new, it is already being replaced. Numerous defects are associated with improper setup, thixotropic behavior or poor surface quality — factors conventional machines cannot identify or address in real time.

Silicone-based adhesives can cause flow, clogging, or uneven application. Some high-viscosity grades may even become virtually impossible to dispense from the cartridge. After dispensing, controlling the excess is challenging. Stringing and tailing are common problems.

With printed circuit boards (PCBs), a mismatch between the dispensing liquid and process can cause stringing and tailing, potentially contaminating the sensitive components on the substrate. Controlling the volume and morphology of the fluid during this process is crucial.

Shot-to-shot repeatability is typically an issue that occurs with manual fluid assembly for low-volume production. Work varies from operator to operator, complicating quality assurance.

AI's Role in Process Optimization and Quality Assurance

Dispensing robots are very efficient, but any process deviation exposes their shortcoming — they complete tasks mindlessly. Their duties may be repetitive, but variables are inevitable.

What happens when a piece is not seated correctly in the fixture or the facility's humidity is relatively high? The robot will dispense adhesive in the wrong place or apply sealant unevenly.

Part placement and material morphology problems are relatively common, so why do manufacturers still rely on machines that can't effectively address them? Machine vision systems are intelligent, enabling them to move beyond preprogrammed paths.

Predict Unexpected Changes

AI can predict changes in adhesive viscosity, which is crucial when dealing with high-viscosity fluids. Its decision-making is based on several factors:

- Flow rate

- Ambient temperature

- Chemical composition

- Nozzle geometry

This analysis allows the machine to adjust dispensing parameters proactively.

Adjust Parameters in Real Time

Algorithms can analyze vision data in real time to adjust dispensing parameters:

- Flow rate

- Dispensing pressure

- Nozzle cleanliness

- Part placement

Correcting unexpected deviations helps ensure bead uniformity. Real-time capabilities are crucial for catching minor inconsistencies before they snowball.

Optimize Dispensing Paths

Even generative AI has automated dispensing applications. They include:

- Path optimization

- Material property analysis

- Formulation optimization

- Dispensing simulation

Leveraging generative technology can reduce programming time and material waste.

How AI and Machine Vision Technology Work Together

Initially, image preprocessing extracts the dispensing area. Then, an algorithm calculates the positioning information by assessing the relationship between geometric transformations.

This process is the foundation of automatic dispensing. AI can further optimize the path or adjust it based on unexpected variables.

One study found that a machine-vision-based automated dispensing system had a matching success rate of over 99% with a repeated extraction accuracy error of less than 0.02 nanometers. The researchers tested the machine on 20 PCBs. Despite decreasing the dispensing path by 723.4 millimeters, efficiency increased by up to 30%.

This research shows that the effectiveness of AI and machine vision technologies is not hypothetical. The specific gains may look different in real-world settings, but they clearly outperform standard, two-dimensional dispensing.

Image credit of Евгений Харитонов / iStock / Getty Images Plus.

How Machine Vision Revolutionizes Automated Dispensing

Computer vision is an umbrella term that encompasses machine vision. It is a subset of AI that enables computers to extrapolate data from their surroundings. Machine learning techniques model the complex dependencies in this visual data to form conclusions or make decisions.

It offers improved precision, production efficiency, and waste reduction, significantly outperforming existing technology. Professionals can use it for real-time process control or quality assurance.

Improve Path Guidance

AI-powered three-dimensional (3D) cameras can generate and improve the path trajectory. These cameras can do the following:

- Map complex part geometries

- Correct deviations

- Regulate nozzle height and angle

- Prevent overapplication

This process is critical for uniform bead application.

Enhance Bead Inspection

AI excels at pattern recognition, so machine vision systems are ideal for quality control. These quality control applications include:

- Identify hidden inconsistencies

- Detect part misalignment

- Enhance production efficiency

- Reduce material waste

In addition to detecting errors, machine vision technology can find the root cause, thereby facilitating a proactive approach. It ensures a previously unattainable quality level.

Integrating AI and Machine Vision into Dispensing Robots

Smart factories are becoming more common, but a lack of sufficient training data hinders widespread adoption. This will no longer be an obstacle once more manufacturers of automation machinery release off-the-shelf systems.

Smart machinery integrates seamlessly with machine learning algorithms, allowing facility operators to easily adapt their existing technology stack to new inputs.

After initial setup, their system will need data integration into relevant factory software, such as manufacturing execution systems or digital twins, to be able to make changes autonomously.

Industries That Can Benefit from Implementation

Many manufacturers could benefit from implementing machine vision technology, despite its high cost. A cost-benefit analysis would clarify its facility-specific impact. Numerous modern applications could benefit from machine vision technology. These include health care organizations, automakers, consumer electronics companies, and defense contractors. It has numerous applications, such as:

- Applying sealant on fuselage panels

- Sealing microscale parts on PCBs

- Applying microdots on electric vehicle batteries

- Bonding medical face masks

Whether facilities assemble electric vehicle batteries or smartphone displays, intelligent dispensing is essential when precision and reliability are nonnegotiable.

The Future of This Novel Technology

Manufacturers of automation machinery are already debuting novel machine-vision-based systems. Predictive analytics and generative AI tools will supplement their capabilities, making these systems a comprehensive solution to current dispensing pain points. As companies implement this technology in their manufacturing operations, this equipment could go from an industry-first product to a common off-the-shelf solution in a few years.

While automated dispensing hardware is already effective, there is room for improvement. Intelligent machine vision technology allows manufacturers to close the gap, bringing their factory floors into the digital age.

Opening image credit of ipopba / iStock / Getty Images Plus.