PRODUCT FOCUS

Packaging System Lowers Carbon Footprint and Reduces Waste

Mixing-technologies provider partners with contract-filling company to offer filling services for sustainable two-component packaging.

Packaging System Lowers Carbon Footprint and Reduces Waste

Mixing-technologies provider partners with contract-filling company to offer filling services for sustainable two-component packaging.

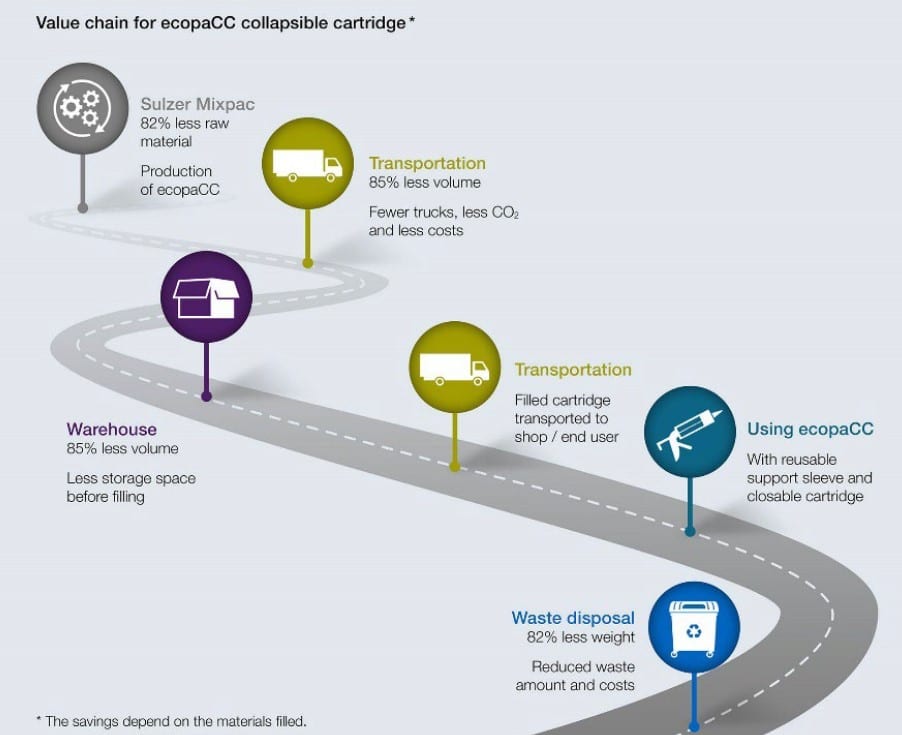

As companies throughout the value chain work to reduce their carbon footprint and the amount of waste they generate, liquid application and mixing technologies provider medmix is offering sustainable packaging solutions for adhesives and sealants used in industrial applications. The MIXPAC™ ecopaCC™ is a collapsible, foil-based packaging system that reduces plastic waste by approximately 75% compared to conventional solid cartridges with equivalent volume, while also saving transportation costs and waste volume. Supporting this, contract-filling provider CTA is offering its customers full contract filling services for the MIXPAC ecopaCC.

The ecopaCC packaging system features collapsible packing technology for applications including structural bonding, chemical anchoring, and sealing and rack repair. These collapsible cartridges are designed for two-component packaging and use a reusable support sleeve for dispensing. Because of its design, the cartridge reduces in size as adhesives are dispensed. The collapsed cartridge weighs less than conventional products, reducing disposal costs. Additionally, its foldable design requires less space, both when it is filled with product and when it is empty.

Figure 2: The ecopaCC when fully compressed – minimal waste

With its unique design, ecopaCC saves CO2 emissions during manufacturing by using a significantly reduced amount of plastic combined with a production process powered by renewable energy. Additionally, the product requires four times less space for shipping, resulting in reduced logistics requirements and emissions during transportation. The collapsible design also means that empty ecopaCC cartridges can be stored, requiring four times less space compared to the solid-cartridge design; this significantly reduces the storage cost of empty cartridges. Additionally, the cartridge’s support sleeve can be re-used up to 1,000 times. The packaging design ensures exceptional mechanical and barrier properties, while offering full compatibility with standard dispensers. Customers can order professionally filled ecopaCC cartridges in any quantity from CTA.

Figure 3: The life of an ecopaCC cartridge – effective and efficient sustainability

CTA provides development, production, filling, packaging, assembling, and logistics services for chemical products. The company regularly supplies solutions used for applications in various industries such as wind energy, automotive, transportation, aerospace, electronics, and chemistry. CTA’s service offering for the ecopaCC packaging system ensures that medmix customers can specify a proven sustainable cartridge to support environmental strategies and reduce emissions.

Franco Menchetti, Sales Manager at CTA, commented, “Using dedicated machines developed ourselves, we may offer tailored ecopaCC filling services for low- to high-viscosity products. Our inherent flexibility as a contract manufacturer ensures we can provide everything from samples to full production runs-delivered anywhere in the world. We also carry out custom labeling to meet various industry or customer-based branding requirements, enabling the production of fully finished products. Our long-standing relationship with medmix since 2006, high technical expertise, a strong logistics network as well as in-house capabilities reflects a complete service offering for the outstanding and sustainable packaging system ecopaCC.”

CTA ensures highest quality with its rigorous testing and inspection processes. These include extrusion and application tests as well as X-ray inspection of filled cartridges for enhanced quality control. Quality inspection for each production run can be tailored to customer-specific requirements or industrial standards. As a result, customers get cartridges filled at the highest quality levels, which enhances the performance.

“We are seeing market pressure in the industrial sector towards more sustainable cartridge and packaging products,” said Christian Majoleth, Product Manager at medmix Switzerland. “This is due to customers wanting to reduce the environmental impact of their business as well as due to tightening regulations around the world regarding emissions and plastic waste reduction. By adopting the ecopaCC, customers can take an important step to achieve their sustainability targets and hence towards an improved CO2 footprint overall.”

Learn more at www.medmix.swiss. Images in article courtesy of medmix.