FEATURE

Accelerating Collaborative Sustainability in the Tapes Industry

Performance Aligned with Sustainability: Polyethylene Wax in Metallocene-Based Hot-Melt Adhesives

Opportunities to increase market share will increase when companies are pre-positioned for growth in a resilient and scalable way.

Performance Aligned with Sustainability: Polyethylene Wax in Metallocene-Based Hot-Melt Adhesives

By Lisa Anderson, Founder and President, LMA Consulting Group

By Marianne Triveloni, Application Engineer, Braskem, Rotterdam, Netherlands

The incorporation of a biobased component can simultaneously provide performance and promote sustainability.

Introduction

Our society continues to face significant challenges in the search for effective solutions to address climate change. Without immediate actions, future generations will face disastrous consequences. Within the adhesives industry, this global concern is driving companies to explore innovative and sustainable alternatives. As a result, manufacturers are being pushed to think creatively and develop formulations that not only meet performance requirements but also contribute to environmental responsibility.

Traditionally, fossil-based materials have been the most common source of raw materials in adhesive production. However, the growing demand for sustainable solutions is accelerating the adoption of renewable alternatives. In this context, there are two different approaches that can contribute directly to the reduction of greenhouse gas (GHG) emissions and support the transition toward a low-carbon economy:

- Biobased (segregated approach): In this model, the biobased content can be physically traced and quantified — typically through C14 analysis using the ASTM D6866, for example.

- Bio-attributed (non-segregated approach): This relies on a mass-balance methodology using renewable feedstock. It enables the allocation of renewable content across production systems, even when physical segregation is not feasible, supporting broader adoption of sustainable materials.

Within the scope of a segregated solution, a polyethylene wax derived from the sugarcane — with a cradle-to-gate carbon footprint of -1.55 kgCO2e/kg for HDPE grades and -1.86 kgCO2e/kg for LDPE grades (Braskem, 2025)1, emerges as a renewable alternative that contributes positively to climate change mitigation while delivering performance.

Waxes are used in different types of adhesives, but their most prominent application is in hot-melt adhesive (HMA) formulations. In these systems, the waxes have the function of acting as a rheology modifier. They help to adjust the viscosity, regulate open time, and improve overall compatibility among components.

Polyethylene waxes used in these systems can be classified into two main types: low-density polyethylene (LDPE) waxes and high-density polyethylene (HDPE) waxes, each offering distinct properties that influence the final performance of the adhesive. Selecting the appropriate wax type is essential to achieving the desired balance between adhesion, thermal resistance, and application-specific requirements.

This article aims to demonstrate how the incorporation of a biobased component can simultaneously provide performance and promote sustainability.

A Hot-Melt Metallocene-Based Formulation Aligned with Sustainability

Hot-melt adhesives (HMAs) are solvent free and use a thermoplastic polymer in their composition, such as metallocene-based polyethylene (mPE) or ethylene-vinyl acetate (EVA), for example. These adhesives are widely used in different applications, like packaging, hygiene, automotive, and construction.

Metallocene-based HMAs offer some advantages over EVA-based formulations, like better thermal stability, low odor, and density — these properties contribute to better processability and performance across a range of applications.

Typical formulations of this type of HMA consist of a thermoplastic polymer — such as metallocene polyethylene (mPE), combined with a resin — such as hydrocarbon resins, waxes (including polyethylene and/or Fischer-Tropsch waxes), and other additives. The composition can be tailored to meet specific performance requirements, depending on the end-use application.

To show how sustainability can walk together with performance, an HMA formulation was developed based on a metallocene polyethylene (mPE — with a melt index of 1000 g/10min @190 °C/2.16 kg – ASTM D1238 and density of 0,870 g/cm3 – ASTM D792), combined with a C5 hydrocarbon resin (softening point: 125 °C – ASTM E28), an antioxidant and a selected polyethylene wax. The component ratios were precisely defined as follows: 37.7% mPE, 25% wax, 37% resin, and 0.3% antioxidant.

Below is a brief description of the wax used in the formulation:

Formulation: Incorporated a high-density polyethylene (HDPE) wax, with the typical values for dropping point of 119 °C (DIN ISO 2176), viscosity at 140 °C of 141mPas (DIN EN ISO 2555), and minimum biobased content of 96% (ASTM D 6866)2.

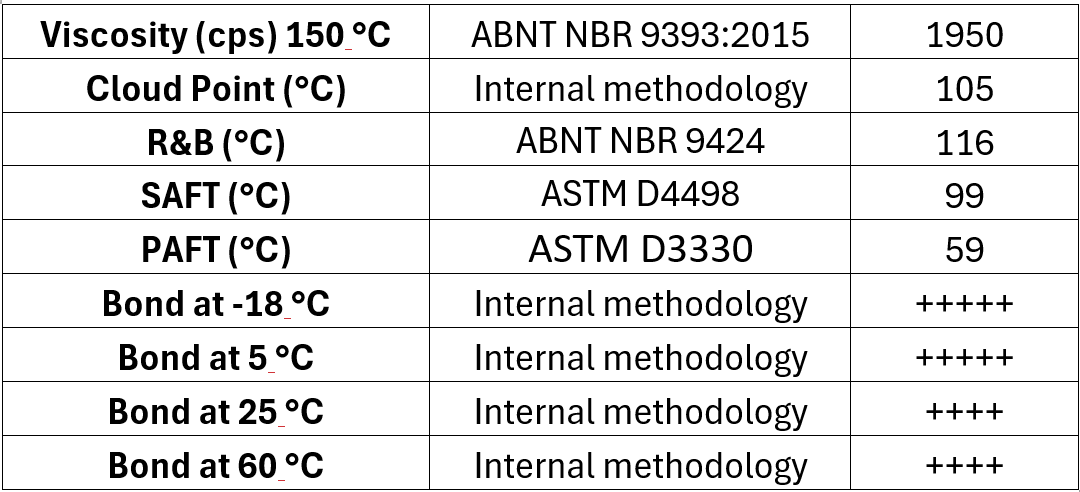

The main properties evaluated in the HMA were the viscosity at 150 °C (ABNT NBR 9393:2015), cloud point (following an internal methodology), softening point — R&B (ABNT NBR 9424), thermal resistance — shear adhesion failure temperature (SAFT) — ASTM D4498 and peel adhesion failure temperature (PAFT) — ASTM D3330, and bonding resistance— following an internal methodology and performed using a carbon board standard — (Cobb NBR NM-ISO 535:1999 = 38 g/m2).

The table below summarizes the results of the HMA formulation.

Table 1: Results of the HMA formulation.

Overall, the results indicated favorable values for both viscosity and softening point properties. As for the cloud point, the internal methodology considers values below 177 °C as indicative of good system compatibility — an outcome successfully achieved by the formulation.

The adhesive results for thermal performance, evaluated through SAFT and PAFT tests, were very positive. These parameters are critical, as they indicate how well the adhesive withstands when exposed to elevated temperatures — a key factor during processes such as transportation or storage in warm environments.

Bonding performance was evaluated across a temperature range from -18 °C to 60 °C. The results revealed strong adhesion, with superior performance at lower temperatures — an essential characteristic for applications such as cold-chain packaging, for example.

Conclusion

The formulation presented in this study is a clear example of how a renewable raw material can be effectively incorporated into a hot-melt formulation with the objective of not only increasing the renewable content of the adhesive but also maintaining high performance standards. The results obtained, particularly in terms of thermal resistance and bonding properties, reinforce the technical viability of this approach.

In this specific case, the wax alone contributes 25% biobased content to the overall formulation. When considering the potential use of other components — such as resins or polymers sourced via mass balance or segregated renewable approaches, the total renewable content of the adhesive could be significantly increased, potentially exceeding 50% depending on the sourcing strategy. This represents a substantial advancement in sustainable adhesive development.

In summary, this study is aligned with the industry's current trends, which are pushing manufacturers and end-users to reduce their carbon footprint and adopt more sustainable practices. Small changes in formulation, like the one demonstrated here, can lead to meaningful environmental impacts when scaled across production lines and product portfolios.

The time to act is now, so that future generations can benefit from the sustainable choices we make today.

For additional information about Braskem, visit braskem.com.

References

1. Braskem. (2025, July). Life Cycle Assessment (LCA) of I`m greenTM bio-based PE wax. Braskem. Internal technical report.

2. Braskem. (2025). GWAX50A – Technical data sheet. Braskem. Retrieved on September 29, 2025, from https://www.braskem.com/productsearch?p=2035.

Opening image courtesy of LightStock / iStock / Getty Images Plus.